What is 3D printing? Also known as additive manufacturing, 3D printing is a transformative technology that enables the creation of complex, three-dimensional objects by depositing material layer by layer. This technology has revolutionized various industries, from aerospace and automotive to healthcare and consumer products, by offering unprecedented design flexibility, reduced lead times, and cost savings.

This guide attempts to answer the common question, “What is 3D printing?” by focusing on the engineering principles and applications of 3D printing, providing a comprehensive understanding of the fundamental concepts, materials, hardware components, software tools, and real-world applications of the technology.

3D Printing Technologies

3D printing, or additive manufacturing, is a process that creates three-dimensional objects layer by layer, following a digital model or blueprint. This technology has gained significant attention in recent years due to its ability to produce complex geometries, reduce material waste, and shorten production times compared to traditional manufacturing methods.

There are several types of 3D printing technologies, each with its own set of advantages and limitations, depending on the specific application and material requirements.

Fused Deposition Modeling (FDM)

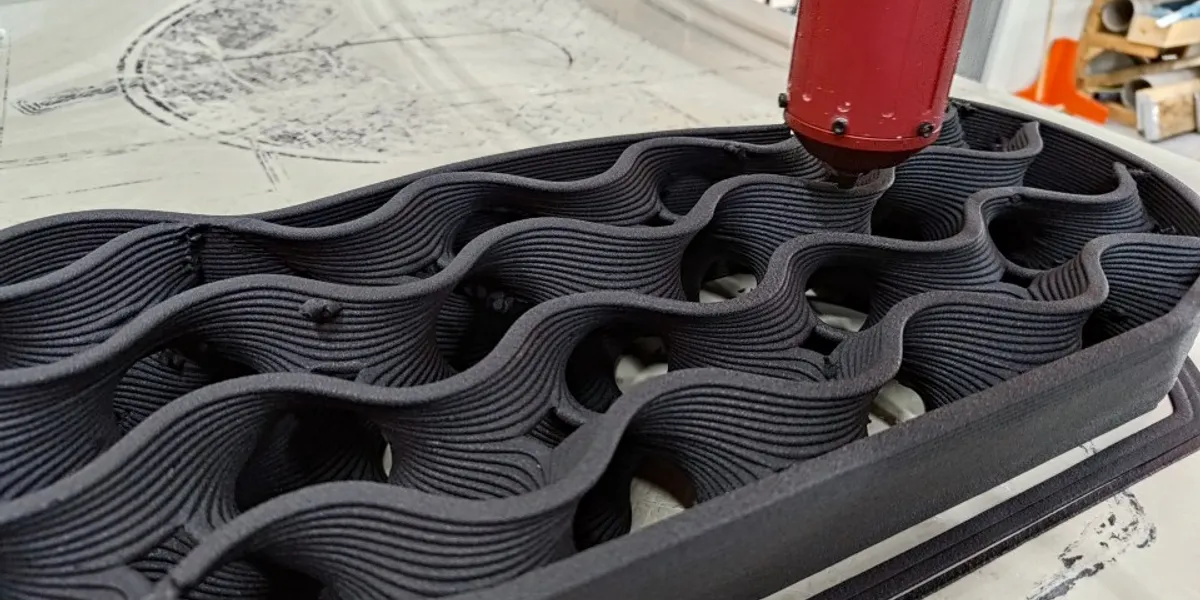

Fused deposition modeling (FDM) or fused filament fabrication (FFF) is one of the most widely used 3D printing technologies, known for its simplicity, affordability, and versatility. FDM works by extruding a thermoplastic filament through a heated nozzle, which deposits the material onto a build platform in a layer-by-layer fashion, following a predetermined path defined by the digital model.

FDM offers several advantages, such as the ability to print with a wide range of thermoplastic materials, including PLA, ABS, and PETG, which have different mechanical and thermal properties suitable for various applications. FDM printers are also relatively affordable and easy to use, making them popular among hobbyists, educators, and small businesses.

However, FDM has some limitations, such as lower resolution and surface finish compared to other 3D printing technologies, as well as the need for support structures when printing overhangs and complex geometries. Parts are also anisotropic; they are weaker along one axis due to weaker bonds between layers.[1] Despite these limitations, FDM remains a popular choice for many 3D printing applications, such as rapid prototyping, functional testing, and low-volume production of plastic parts.

Further reading: FFF vs FDM: Is There Any Difference?

Stereolithography (SLA)

Stereolithography (SLA) is another widely used 3D printing technology that creates objects by selectively curing a liquid photopolymer resin using ultraviolet (UV) light. SLA offers higher resolution and surface finish compared to FDM, making it suitable for applications that require intricate details and smooth surfaces.

The SLA process involves the use of a UV laser that traces the cross-sectional pattern of the object onto the surface of the liquid resin, causing it to solidify and adhere to the build platform or the previous layer. The build platform is then incrementally lowered, allowing the next layer of resin to be exposed and cured. This process is repeated until the entire object is built.

SLA offers several advantages over FDM, such as higher resolution, smoother surface finish, and the ability to produce more intricate and complex geometries. However, SLA also has some limitations, such as the need for support structures to prevent deformation and the relatively limited range of available materials, which are primarily limited to photopolymer resins. These resins can be brittle and may degrade over time when exposed to UV light, making them less suitable for certain applications.

Despite these limitations, SLA is a popular choice for applications that require high-resolution and detailed parts, such as jewelry, dental models, and prototypes for injection molding. By understanding the principles and capabilities of SLA, engineers can leverage this technology to create high-quality, intricate objects that are difficult or impossible to produce using other 3D printing methods.

Further reading: How do Resin Printers Work: SLA, DLP & More

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a 3D printing technology that uses a high-power laser to fuse powdered material, such as nylon, polyamide, or metal, into solid objects layer by layer. SLS is known for its ability to produce durable and functional parts with complex geometries and good mechanical properties, making it suitable for a wide range of applications, from prototyping to end-use products. Most SLS systems are targeted at professional or industrial users rather than hobbyists or small businesses.

In the SLS process, a thin layer of powdered material is spread across the build platform, and a laser scans the surface, following a predetermined pattern that corresponds to a cross-section of the object being printed. The laser heats the powder to a temperature just below its melting point, causing the particles to fuse together and form a solid layer. Once a layer is completed, the build platform is lowered, and a new layer of powder is spread on top. This process is repeated until the entire object is printed.

One of the key advantages of SLS is its ability to produce parts with complex geometries and internal structures, such as lattice structures and hollow cavities, without the need for support structures.[2] This is because the unfused powder surrounding the printed part acts as a natural support, preventing deformation and allowing for the creation of intricate designs. SLS also offers good mechanical properties.

However, SLS also has some limitations, such as the need for post-processing to remove excess powder and improve surface finish, as well as the relatively high cost of the equipment and materials compared to other 3D printing technologies like FDM and SLA.

Further reading: SLS Printing: Unlocking the Potential of Selective Laser Sintering

Direct Metal Laser Sintering (DMLS)

DMLS can produce production-quality

Direct metal laser sintering (DMLS) or powder bed fusion (PBF) — sometimes referred to by the proprietary term Selective Laser Melting (SLM) — is an advanced, industrial-grade 3D printing technology specifically designed for printing metal parts. The process involves using a high-power laser to selectively fuse metal powders, layer by layer, into fully dense and functional metal components. DMLS offers exceptional precision and allows for the creation of complex geometries that would be challenging or impossible to achieve using traditional manufacturing methods.

The versatility of DMLS allows for the use of various metal materials, such as stainless steel, aluminum, titanium, and even high-performance alloys, making it well-suited for applications in aerospace, automotive, medical, and other industries that demand durable and high-quality metal parts. It is capable of producing production-quality metal parts as well as prototypes.

One of the advantages of DMLS is its ability to produce parts with excellent mechanical properties, approaching or even exceeding the strength of conventionally manufactured components. However, the process can lead to residual stresses and warping, necessitating careful design considerations and post-processing steps to achieve the desired properties and dimensional accuracy. DMLS machines and materials require careful handling and should only be used in an industrial environment.

Further reading: Metal Manufacturing Processes Compared: Machining, Forging, Casting, Powder, Additive, Extrusion

Electron Beam Melting (EBM)

Electron beam melting (EBM) is an additive manufacturing technology that utilizes an electron beam to selectively melt and fuse metal powders into complex and fully dense 3D parts. EBM is particularly well-suited for printing high-performance metal components with excellent mechanical properties.

During the EBM process, a focused electron beam scans the surface of a powdered metal bed, melting the material in specific regions based on the digital model’s cross-section. As each layer is completed, the build platform is incrementally lowered, and a new layer of powder is spread on top. This layer-by-layer approach enables the creation of intricate geometries and internal structures without the need for support structures.

EBM offers distinct advantages, including its ability to produce parts with superior material properties, especially in terms of mechanical strength and fatigue resistance. This makes EBM a preferred choice for critical applications in aerospace, medical implants, and the automotive industry.

However, EBM has certain limitations, such as slower build times compared to some other metal 3D printing methods like DMLS. Additionally, the high vacuum environment required for the process and the specialized equipment can contribute to higher capital costs.[3] Despite these factors, EBM remains a powerful technology for fabricating high-quality metal components that meet the stringent requirements of demanding industries.

Directed Energy Deposition (DED)

Directed energy deposition (DED) is an additive manufacturing technique that involves the precise deposition of material, typically metal powders or wires, onto a substrate using a high-energy heat source, such as a laser or an electron beam. DED is known for its versatility, as it allows for the repair, modification, or building up of existing parts, making it valuable for industries that deal with large-scale components and expensive materials.

During DED, the heat source melts the material as it is being deposited, resulting in excellent metallurgical bonding with the substrate or previous layers. This process enables the creation of near-net-shape parts, reducing material waste and minimizing post-processing requirements.

DED finds applications in various industries, including aerospace, oil and gas, and automotive, where it is used for repairing worn-out components, adding features to existing parts, or building custom-designed structures with a wide range of materials. However, the process can introduce thermal stresses and distortion, necessitating careful process control and stress relief techniques.

Binder Jetting

Binder jetting is an additive manufacturing process that utilizes a liquid binding agent to selectively fuse powdered materials, such as sand, metal, or ceramics, into solid objects. The process begins with the spreading of a thin layer of powder on the build platform. A print head then deposits the liquid binder onto the powder in a pattern defined by the digital model’s cross-section.

One of the key advantages of binder jetting is its ability to print large and complex parts quickly, making it suitable for applications in architecture, aerospace, and automotive industries. Additionally, the technology allows for the production of sand molds and cores for metal casting processes without the need for a pattern, greatly reducing lead times.[4]

However, binder jetting typically produces parts with lower mechanical properties compared to technologies like DMLS or SLS. Post-processing steps, such as sintering to improve material strength and surface finish, are often necessary. Despite these considerations, binder jetting remains an attractive choice for rapid and cost-effective prototyping and production of parts in a variety of materials.

Further reading: Binder Jetting: A Comprehensive Guide to the Additive Manufacturing Process

3D Printing Materials

Selecting the appropriate material for a 3D printing project is crucial, as it directly impacts the final product’s properties, appearance, and performance. Various materials are available for 3D printing, each with its own set of characteristics and applications. By understanding the properties and applications of different 3D printing materials, engineers can choose the most suitable material for their specific project requirements and constraints.

Thermoplastics

Thermoplastic polymers are a widely used material in 3D printing, particularly in fused deposition modeling (FDM) processes, where they take the form of filament, and in selective laser sintering (SLS), where they come in powder form. Thermoplastics are characterized by their ability to be repeatedly melted and solidified, allowing them to be extruded and deposited layer by layer to form a 3D object. Some common thermoplastics used in 3D printing include PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), and PETG (polyethylene terephthalate glycol).

PLA is a biodegradable and environmentally friendly thermoplastic derived from renewable resources, such as cornstarch and sugarcane. It is popular for its ease of use, low odor, and relatively low printing temperature, making it suitable for beginners and applications that do not require high mechanical strength or temperature resistance.

ABS is a petroleum-based thermoplastic known for its strength, durability, and heat resistance. It is commonly used in applications that require higher mechanical strength and durability, such as automotive parts, electronic enclosures, and toys. However, ABS can be more challenging to print with due to its higher printing temperature and tendency to warp, and it may produce unpleasant fumes during the printing process.

PETG is a modified version of PET, a widely used plastic in food packaging and other consumer products. PETG combines the ease of use and environmental friendliness of PLA with the strength and durability of ABS, making it a versatile material for various applications. PETG is resistant to chemicals and moisture, making it suitable for outdoor and industrial applications, as well as food-safe containers and medical devices.

Nylons or polyamides are thermoplastics known for their excellent mechanical properties, including high strength, toughness, and flexibility. They are commonly used in FDM (filament) and SLS (powder) for applications that demand robust and durable parts, such as functional prototypes, mechanical components, and industrial tools.

Photopolymers

Photopolymeric resins can be printed using

Photopolymers are light-sensitive materials that undergo a chemical change when exposed to a specific wavelength of light, such as ultraviolet (UV) light. In the context of 3D printing, photopolymers are commonly used as the base material for technologies like stereolithography (SLA) and digital light processing (DLP), where the curing process is driven by a light source.

Photopolymers used in 3D printing are typically liquid resins that solidify when exposed to light, forming the desired object layer by layer. These resins are available in a wide range of formulations, each with its own set of properties and characteristics, such as mechanical strength, flexibility, and biocompatibility.

Standard resins are general-purpose photopolymers that offer a balance between cost, ease of use, and material properties. They are suitable for a wide range of applications, such as prototyping, art, and design. Standard resins are available in various colors and can be post-processed to achieve different surface finishes.

Engineering resins are specialized photopolymers designed for specific applications that require enhanced material properties, such as high strength, heat resistance, or chemical resistance. These resins are often used in industries like automotive, aerospace, and electronics, where the printed parts need to withstand demanding conditions or meet strict performance requirements.

Biocompatible resins are photopolymers that have been tested and certified for use in medical and dental applications, such as surgical guides, dental models, and custom prosthetics. These resins are formulated to meet strict biocompatibility standards, ensuring that they are safe for contact with human tissue and fluids.

Metals

Metals, typically formulated as powders, are an important class of materials used in 3D printing processes such as direct metal laser sintering (DMLS) and electron beam melting (EBM). These processes involve the use of a high-energy laser or electron beam to selectively fuse metal powder particles together, layer by layer, to form a solid object. Metal powders enable the production of high-strength, lightweight, and complex parts that are difficult or impossible to manufacture using traditional methods.

Metal powders used in 3D printing are typically produced through processes such as gas atomization, water atomization, or mechanical milling. These processes create fine metal particles with a specific size distribution and morphology, which can affect the flowability, packing density, and sintering behavior of the powder during the 3D printing process. With processes like directed energy deposition (DED), metal wire can be used as feedstock instead of powder.

Some common metals used in 3D printing include stainless steel, titanium, aluminum, and nickel-based alloys. These metals offer a range of mechanical, thermal, and corrosion-resistant properties, making them suitable for various applications, such as aerospace, automotive, medical, and energy.

Stainless steel is a popular metal powder for 3D printing due to its combination of strength, corrosion resistance, and affordability. It is commonly used for functional prototypes, tooling, and end-use parts in industries such as automotive, aerospace, and consumer products.

Titanium is a lightweight, high-strength metal with excellent biocompatibility and corrosion resistance, making it ideal for aerospace, medical, and automotive applications. Titanium’s high strength-to-weight ratio and resistance to fatigue make it particularly well-suited for load-bearing components and structures.

Aluminum is a lightweight, corrosion-resistant metal with good thermal conductivity and electrical conductivity. It is often used in 3D printing for applications that require lightweight, high-strength parts, such as aerospace components, automotive parts, and electronic devices.

Nickel-based alloys, such as Inconel and Hastelloy, are high-performance metals with excellent strength, corrosion resistance, and high-temperature stability. These alloys are commonly used in 3D printing for applications in the aerospace, energy, and chemical processing industries, where parts are exposed to extreme temperatures and corrosive environments.

Other

Plastics and metals are the most widely used materials in 3D printing, but there are other more niche materials that can be used with certain processes. These include composites, ceramics, and biomaterials.

Composites are materials that combine a base material with a supplementary reinforcing material. In FDM 3D printing, for example, thermoplastic polymers can be mixed with glass or carbon fibers to provide added strength and stiffness. In most composite filaments, these fibers have a random orientation, but some 3D printing companies have developed technology for printing continuous fibers, giving printed parts superior strength.

Biomaterials are a class of materials used in 3D bioprinting, a niche form of 3D printing that aims to create biomedical parts that imitate natural tissue. The most prevalent biomaterials are bio-inks that can be dropped or extruded in complex patterns, allowing researchers to create tissue and organ models for vital applications like drug testing. One of the long-term end goals of bioprinting is to create artificial human organs for transplantation.

Ceramic and sand materials can be 3D printed using processes like binder jetting, in which a liquid binding material is used to join particles of the material together. Ceramic resins can also be used with photopolymerization technologies like stereolithography, while clay pastes can be used with large-format extrusion technologies. 3D printed sand is particularly useful in the foundry industry for the fabrication of sand molds.

Further reading: The Ultimate Guide to Types of 3D Printing Materials

3D Printing Software

3D printing projects require a variety of software components and tools, including 3D modeling software, slicing software, and printer control software. These software tools enable engineers to design, prepare, and optimize 3D models for printing, taking into account the unique requirements and constraints of the target hardware and material. Note that professional and industrial 3D printer hardware is more likely to come with associated proprietary software.

3D Modeling Software

3D modeling or computer-aided design (CAD) software is a crucial tool in the 3D printing process, as it allows engineers to create and modify digital representations of the objects they wish to print. These digital models can be exported in various file formats, such as STL, OBJ, or 3MF, which can then be processed by slicing software to generate the instructions for the 3D printer.

There are several 3D modeling software options available, each with its own set of features, capabilities, and learning curves. Some popular 3D modeling software includes Autodesk Fusion 360, Blender, and Tinkercad.

Autodesk Fusion 360 is a cloud-based 3D modeling software that combines parametric and direct modeling techniques, making it suitable for both mechanical engineering and industrial design applications. Fusion 360 offers a wide range of tools for creating, modifying, and analyzing 3D models, as well as integrated simulation and manufacturing capabilities.

Blender is a free and open-source 3D modeling software that is widely used for various applications, including animation, visual effects, and game development. Blender offers a comprehensive set of modeling, sculpting, and texturing tools, as well as support for various file formats and third-party plugins. Although Blender has a steep learning curve, its powerful features and active community make it a popular choice for 3D printing enthusiasts.

Tinkercad is a browser-based 3D modeling software that is designed for beginners and educational settings. Tinkercad offers a simple and intuitive interface, allowing users to create and modify 3D models using basic shapes and operations. While Tinkercad may not have the advanced features of other 3D modeling software, its ease of use and accessibility make it a popular choice for those new to 3D printing.

Slicing Software

Slicing software is an essential component of the 3D printing process, as it translates the 3D model into a series of instructions, called G-code, that the 3D printer can understand and execute. The slicer takes the digital model, usually in the form of an STL, OBJ, or 3MF file, and divides it into thin layers of material. It then generates the toolpaths and control commands for the printer’s extruder, laser, or other deposition system to follow as it builds the object layer by layer.

Some popular slicing software includes Cura, PrusaSlicer, and MatterControl. These programs offer a range of features and settings that allow users to customize the printing process, such as layer height, infill density, and support structures.

Cura is an open-source slicing software owned by Ultimaker, a leading manufacturer of 3D printers. Cura offers a user-friendly interface and a wide range of settings and features, making it suitable for both beginners and experienced users. Cura supports a variety of 3D printers and materials and includes features such as adaptive layer height, tree supports, and ironing for improved surface finish.

PrusaSlicer is an open-source slicing software developed by Prusa Research, a well-known 3D printer manufacturer. PrusaSlicer is based on the popular Slic3r software but has been extensively modified and improved to provide a more streamlined and user-friendly experience. PrusaSlicer offers features such as variable layer height, customizable support structures, and seam hiding, as well as built-in profiles for Prusa 3D printers and materials. It is used for FDM and SLA 3D printing.

MatterControl is a slicing software and printer control application developed by MatterHackers, a 3D printing retailer and community. MatterControl offers a range of features and settings for 3D printing, as well as integrated printer control and monitoring capabilities. Some of its features include automatic bed leveling, real-time slicing, and support for multiple extruders and materials.

3D Printing Applications

3D printing has a wide range of applications across various industries, enabling the creation of complex, customized, and functional parts with reduced lead times and costs compared to traditional manufacturing methods. Some of the most promising applications of 3D printing include rapid prototyping, custom manufacturing, and bioprinting, among others.

Rapid Prototyping

Rapid prototyping is one of the most common applications of 3D printing, as it allows designers and engineers to quickly create physical models of their designs for evaluation, testing, and refinement. By using 3D printing for prototyping, companies can significantly reduce the time and cost associated with traditional prototyping methods, such as CNC machining and injection molding.

3D printing enables rapid prototyping by allowing for:

-

Fast turnaround times, as 3D printed parts can be produced within hours or days, depending on the complexity and size of the part.

-

Design flexibility, as 3D printing can create complex geometries and internal structures that would be difficult or impossible to achieve with traditional manufacturing methods.

-

Iterative design, as designers can quickly create multiple versions of a part, test them, and make adjustments as needed.

Rapid prototyping using 3D printing is widely used in industries such as automotive, aerospace, consumer electronics, and product design, where the ability to quickly create and test physical prototypes is crucial for reducing time-to-market and ensuring the success of new products. By leveraging the capabilities of 3D printing, companies can streamline their product development process, improve design quality, and gain a competitive advantage in the market.

Custom Manufacturing

Custom manufacturing is an application of 3D printing that allows for the production of unique, tailor-made parts and products that cater to specific customer requirements or design constraints. By leveraging the design flexibility and rapid prototyping capabilities of 3D printing, custom manufacturing enables the creation of one-of-a-kind items or small-batch production runs without the need for expensive tooling or molds.

One of the key advantages of custom manufacturing using 3D printing is the ability to create complex geometries and internal structures that would be difficult or impossible to achieve with traditional manufacturing methods. This capability allows for the development of lightweight, high-performance parts with optimized material usage and reduced waste.

Another benefit of custom manufacturing with 3D printing is the potential for personalization and customization. By using digital models and parametric design tools, engineers can easily modify and adapt designs to meet individual customer preferences or specific application requirements. This level of customization can lead to improved product performance, enhanced user experience, and increased customer satisfaction. A key example of end-user customization can be found in healthcare, where 3D printing technologies like DMLS can be used to create patient-specific titanium implants.

Custom manufacturing with 3D printing is particularly well-suited for industries such as aerospace, automotive, medical, and consumer products, where the demand for unique, high-performance parts is growing. Some examples of custom manufacturing applications using 3D printing include personalized prosthetics, custom-fit dental appliances, and bespoke automotive components.

On-Demand Spare Parts

One of the transformative applications of 3D printing is the ability to produce low-cost, on-demand spare parts for various industries. Traditional supply chains often involve maintaining large inventories of spare parts, which can be costly and space-consuming. Additionally, sourcing and shipping these parts from suppliers can lead to delays and downtime for businesses and consumers.

With 3D printing, companies can implement a digital inventory system for spare parts. Instead of storing physical objects in warehouses, they can keep printable digital files of 3D models ready for production. When a customer or a business needs a replacement part, it can be 3D printed locally or at a centralized facility, depending on the distribution network.

The benefits of using 3D printing for on-demand spare parts include:

-

Reduced lead times: 3D printing allows for rapid production of spare parts, reducing lead times compared to traditional manufacturing methods. Customers can receive the required parts quickly, minimizing equipment downtime.

-

Cost-effectiveness: Keeping digital files of spare parts reduces the need for large physical inventories, saving storage costs. Moreover, 3D printing spare parts as needed can be more cost-effective than producing parts in bulk.

-

Improved supply chain resilience: By decentralizing spare parts production through 3D printing, companies can enhance their supply chain resilience. Local production can mitigate disruptions caused by transportation issues or international restrictions.

-

Obsolescence management: For industries dealing with older equipment or machinery, 3D printing can be a lifesaver. When traditional manufacturing processes become obsolete or uneconomical, 3D printing can still reproduce the necessary parts.

-

Sustainability: On-demand spare parts production can reduce waste and contribute to a more sustainable approach to manufacturing. Companies can avoid overproduction and disposal of excess inventory.

The on-demand spare parts application of 3D printing is already gaining traction in sectors like aerospace, automotive, industrial machinery, and healthcare. As the technology advances and materials improve, its adoption is likely to expand to more industries in the future.

Conclusion

Throughout this guide, we have explored the engineering principles and applications of 3D printing, covering the fundamental concepts, materials, hardware components, software tools, and real-world applications. By understanding the technical depth of 3D printing, you can appreciate its transformative impact on various industries and its potential to reshape our daily lives. As 3D printing technology continues to advance, it will play an increasingly important role in a wide range of applications, from rapid prototyping and custom manufacturing to bioprinting and healthcare.

Frequently Asked Questions

1. What is 3D printing?

3D printing is an additive manufacturing process that creates three-dimensional objects by depositing material layer by layer based on a digital model.

2. What are some common materials used in 3D printing?

Common materials used in 3D printing include thermoplastics, such as PLA, ABS, and PETG; photopolymers, such as standard resins and engineering resins; and metal powders, such as stainless steel, titanium, and aluminum.

3. What software tools are used in the 3D printing process?

Software tools used in the 3D printing process include 3D modeling software, such as Autodesk Fusion 360, Blender, and Tinkercad; slicing software, such as Cura, PrusaSlicer, and MatterControl; and printer control software, which is often specific to the 3D printer being used.

4. How much does a 3D printer cost?

The cost of a 3D printer can vary widely depending on factors like the technology used, size, and capabilities. Entry-level desktop 3D printers can range from $200 to $1,000, while industrial-grade models for printing metal powders can cost hundreds of thousands of dollars.

5. What are the challenges and future prospects of 3D printing?

Some of the challenges in 3D printing include the need for high-resolution and smooth surface finishes, the ability to print with a wide range of materials, and the development of more efficient and cost-effective printing processes. Despite these challenges, 3D printing has the potential to transform industries and improve our daily lives, driving advancements in areas such as rapid prototyping, custom manufacturing, and bioprinting.

6. Who invented 3D printing?

3D printing was invented by Chuck Hull in 1983. He developed the first 3D printing technology, called stereolithography (SLA), and later co-founded 3D Systems Corporation, one of the leading companies in the 3D printing industry.

References

[1] Bellini A, Güçeri S. Mechanical characterization of parts fabricated using fused deposition modeling. Rapid Prototyping Journal. 2003 Oct 1;9(4):252-64.

[2] Kruth JP, Vandenbroucke B, Van Vaerenbergh J, Mercelis P. Benchmarking of different SLS/SLM processes as rapid manufacturing techniques. Laser. 2005 Apr 20;1:3D.

[3] Larsson M, Lindhe U, Harrysson OL. Rapid manufacturing with Electron Beam Melting (EBM)-A manufacturing revolution?. In2003 International Solid Freeform Fabrication Symposium 2003.

[4] Gibson I, Rosen D, Stucker B, Khorasani M, Gibson I, Rosen D, Stucker B, Khorasani M. Binder jetting. Additive manufacturing technologies. 2021:237-52.